How the Internet of Things can Impact Modular Construction

Modular construction has become an emerging building technique over the past few decades because of the efficient way it is able to deliver projects. By building a structure in a factory environment, companies are able to streamline the building process by assembling a building in an assembly-line style.

Because of this, modular construction companies typically have more in common with a manufacturer than an actual construction company. This difference offers modular constructors a number of benefits over traditional construction companies.

In much the same way, The Internet of Things looks to provide companies with a variety of ways to streamline their traditional work processes.

What is The Internet of Things?

The Internet of Things is the connection of devices to one another via the internet, allowing them to constantly send data and information to one another. Think of it in terms of a smart object, similar to a smart-phone. A regular phone just makes calls and texts, but a smart-phone does all of that while connecting to the internet, live-updating your current score on the candycrush leaderboard.

Similarly, a smart piece of equipment would produce live reports on the equipment's use, time since last maintenance, usage, downtime percentage, time since last downtime, etc. to give companies more data on the equipment their using.

Let's say modular construction companies start implementing The Internet of Things into their work processes...

Performance Prediction

Performance (or production) prediction is already a huge part of modular construction. Being able to accurately and effectively predict how quickly a project can be delivered is a huge part of the value that is delivered to the customer. And being being able to shrink that lead time number provides even more value on top of that.

Most modular construction supervisors likely have a pretty good idea on the amount of time that should be spent in a given area of a project. For example, the production supervisor likely has a knows how long it takes to put a roof on a "standard" unit.

However, The Internet of Things allows supervisors and managers to have a much better idea of the actual time taken for these processes. And they are instantly made aware of the process efficiencies and degradations.

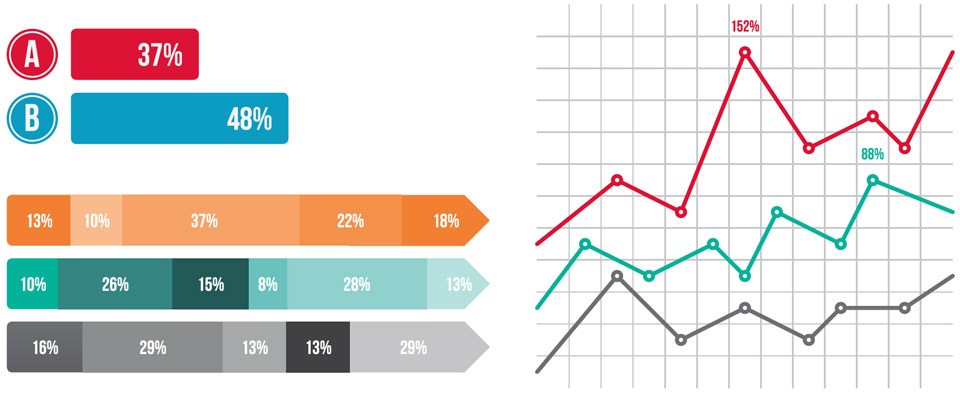

You can think of it as a stock ticker. The IOT allows you to see slight trends in different areas of your factory. Roofers efficiency ↑3.27% over the past week. Well, looks like that new training is really helping the guys.

The same thing works with negative trends. Degradation in work processes is easier to notice and solve quickly. With real-time information like that, it is easier for managers to see what is working, what is not working, and how it will change in the future.

Supply Chain Optimization

Internet of Things applies to a variety of different manufacturing aspects outside of smart equipment. Special tags can be placed on machinery, equipment, and materials to make them a part of IOT instantly. RFID (or Radio Frequency IDentification tags) allow to instantly update the flow of materials into, out of, and through your facility.

RFID tags work a lot like barcodes in that each type of material will have a unique RFID. Your IOT system will be able to pick up this frequency and tell at what that material is doing at any particular point in time. By seeing the actual consumption rate of your materials, companies can better estimate the exact point in which new materials need to be ordered and delivered to the facility.

In this case, the IOT of things helps prevent modular project delays due to an oversight in the supply chain. At the same time, it also helps ensure companies do not keep too much of a material they hardly use either. Again, this helps keep your project lead times more predictable and helps your reduce shipping delays due to materials.

Equipment Monitoring

In the modular construction industry, one of the main benefits is minimal downtime. Unlike a traditional construction site, modular builders do not have delays due to inclement weather. However, all fabricators and builders can find themselves at the mercy of their own equipment.

As mentioned previously in the post, when incorporating the IOT into your construction equipment and tools, you are going to get a lot more information on said equipment. With the amount of measurements that these sensors provide, it will tell you practically everything you could need to know about your machines. This is information is sent out in a constant stream to be analysed and help predict how the equipment will act in the future.

This will help management schedule maintenance on the equipment to keep downtime to a minimum. Also, they can notice other trends measurements of the equipment that might lead to downtime. Noticing these high or low measurements and correcting them before they become a problem is a huge part of IOT equipment maintenance.

Overall, The Internet of Things can potentially turn a modular construction facility into one big web of connected pieces of equipment, materials, and workers. Each individual object in the facility has the ability to be monitored in some form or another to keep the factory running as efficiently as possible.

How does IOT help do this?

By recording mountains of data and then allowing you to interpret that data. From there, it turns it into actionable information which can help you to optimize your factory's work processes.

What IOT really boils down to is a principle that Panel Built and thousands of companies around the world have been working on for years, perfect lean manufacturing. Eliminating wastes in inventory, motion, waiting, defects... these are all the top goals of the Internet of Things, allowing companies to maximize what they have and making it work best for them.