Modular Office Wall Panel Facing Options

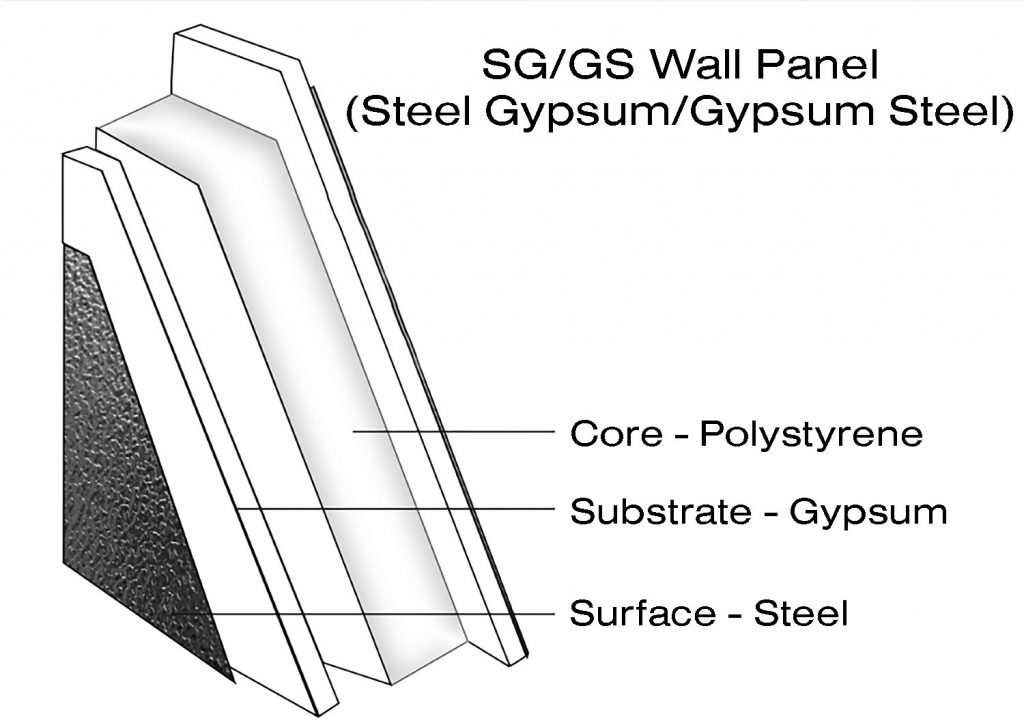

One of the biggest benefits Panel Built provides our customers is the flexibility of a custom composite panel system. For those unfamiliar, composite walls refers to a wall system that uses a variety of different material sources. This way, depending on the application, Panel Built can adapt a panel type that perfectly fits the customer's needs. For example, Panel Built's wall system typically consists of three components: a core, a substrate, and a facing/skin/surface.

For a substrate (the layer between the skin and core), Panel Built primarily uses a gypsum board. Gypsum is the most popular option for a number of reasons. First, and most importantly, it is a very affordable material that adapts well to a number of applications. It does not add a lot of unnecessary weight to the panel and provides good fire protection and sound resistance. Additionally, we utilize a variety of wood board type substrates that can help boost the rigidity and strength of the wall panel, including a sound stop board that increases the STC (Sound Transmission Class) rating of the panel.

For our core options, standard panel built modular wall systems will have a polystyrene core. The polystyrene core is most often paired with our gypsum substrate because they share similar benefits: a low-cost material with a good R-Value (insulation) and STC rating. Similar to Polystyrene, we also provide a Poly-ISO core which is a higher density material, providing higher fire resistance. However, for our one hour fire rated and non-combustible panels, we utilize a mineral wool core to give our panels even more fire protection.

With that out of the way, let's get into the part of the panel you'll actually get to see, the facing/surface layer!

Standard Vinyl Skin

Our most common modular office wall facing is our standard vinyl surfacing. Our vinyl covering is most often going to be found used with our Gypsum/Gypsum wall panel because it is one of the most cost effective opti that we have. This standard panel, consisting of Vinyl skin, gypsum board, and a polystyrene core is by far our most popular panel option because it can be applied to a wide variety of applications, all at a low cost.

For the vinyl skin itself, it's commonly used because it is a relatively durable material while providing a nice finish for the panel. Panel Built's standard vinyl sheets come in three standard color options: white, champagne, and gray. In the instance that there is damage done to the vinyl facing this skin can be easily repaired to make the panel look as good as new.

This panel surface can be found in a variety of settings. In military, warehousing, and manufacturing environments, vinyl skinned wall panels are used because of their cost-effectiveness and their ability to stand up to wear and tear. However, the facing also has the contemporary feel to fit into commercial office and even educational settings.

Stucco Embossed Steel Skin

Our next most popular panel surface option is our stucco embossed steel skin. Our steel skinned walls can be paired with a variety of substrates, or many cases, no substrate at all, giving you a simple Steel/Polystyrene/Steel (or just Steel/Steel) panel. Our Steel/Steel panel provides offers a slightly higher R-Value and lower STC rating than our Gypsum/Gypsum. The steel skins come in one of three standard color options white, gray, and saddle tan.

The biggest benefit of selecting the steel skin for our wall panels is the additional protection that is gives the panel itself. Especially in high traffic areas, modular offices can be susceptible to bumps, kicks, dings, etc. which can really wear on it over time. However, the steel/steel panel is made to withstand these smaller impacts and can be easily cleaned if it collects dirt and grime over time. For these reasons, our steel skinned panels are also the type recommended for all of our exterior buildings.

Fiberglass Reinforced Plastic

Another one of our wall panel surface options is fiberglass reinforced plastic (or FRP) and it has a few unique, but not uncommon applications. One of the most important characteristics of FRP is that it is non-porous and has a high resistance to chemicals. This makes the skin very effective in environments that need to be heavily cleaned or susceptible to high moisture levels. For this reason, FRP panels are often used in restroom and modular cleanroom applications. Additionally, the .08" skins are very tough and low maintenance without breaking your budget.

Smooth Variations of Each

Like our smooth FRP option, our other two surface options come with their own smooth variations. For our smooth steel panels, they are often used to provide our office systems with a very sleek and contemporary look. For example, the two-story modular office system above utilizes a custom, black smooth steel panel with brushed aluminum extrusions. With companies looking to make their manufacturing facilities more and more modern and stylish, our smooth black modular offices have become more and more popular.

For our smooth vinyl covered gypsum wall panel, will often be requested as an alternative smooth surface for a cleanroom system or as an option for a modular office system. It has a similar aesthetic to our smooth steel option with a glossy colored finish but has physical characteristic similar to our FRP panel, being resistant to water and giving off airborne micro-particles.

Don't see what you're looking for here? Don't sweat it! Panel Built is always open to customizing and expanding our wall facing options. If you have a unique wall cover requirement, just let us know, and we will see if we can incorporate it into our panel system!

If you have any questions, just give us a call at 800-636-3873, send us an email to info@panelbuilt.com, or you can simply ask us in our on-page LiveChat feature in the bottom right of your screen. We are always happy to help!