The Best Way To Ensure A Quality Building Project

Undertaking a new construction project can be entirely daunting, especially if you are not an expert. In many cases, we strive to get the project done as quickly and cheaply as possible, but this can often lead to cut corners and poor craftsmanship. Plus, if you live in a remote or rural area, there may not be the talent you need locally to get the job done right. However, Panel Built's modular construction techniques are specifically aimed to ensure a quality building project time after time. Through modular construction, Panel Built can craft custom buildings, AND deliver them to areas throughout the United States. Working in the modular construction industry for 25 years, Panel Built's prefabricated construction methods are trusted with companies and organizations ranging from the United States Military to Fortune 500 Companies. In this post, we will delve into how Panel Built crafts its quality structures, and why they ensure a constant, durable building solution.

Modular construction is a building method that has been in use since the 19th century. Since its origination, modular construction has been developed specifically to deliver consistent, quality building projects. With traditional construction methods, all of the building construction occurs at the project site. Because each job site, construction crew, and project is different, this can create a lot of variables. High foot traffic, inconsistent labor quality, inclement weather, on-site accidents, damaged materials, logistics issues, heavy machinery... The list of possible problems that can occur with stick-built construction goes on and on. The focus of modular construction is to eliminate as many of these variables as possible. Modular construction takes place in a controlled factory environment. To best explain it, it is easiest to think of a traditional assembly line that you see for most mass-produced products like cars, toys, electronics, etc... Panel Built's modular buildings are built in stages in this environment. For Panel Built, we deliver our buildings in one of two methods, knock-down or pre-assembled (depending on what is most efficient for that particular project). These two building methods allow Panel Built, Inc. to deliver modular construction projects of all shapes and sizes, capable of assembling buildings at the project site that end up being multiple times larger than what could fit on the bed of a single flatbed truck. These structures include interior buildings, metal work platforms, guard shacks, equipment buildings, military towers, cleanrooms, ballistic rated buildings, and more!

Modular construction is a building method that has been in use since the 19th century. Since its origination, modular construction has been developed specifically to deliver consistent, quality building projects. With traditional construction methods, all of the building construction occurs at the project site. Because each job site, construction crew, and project is different, this can create a lot of variables. High foot traffic, inconsistent labor quality, inclement weather, on-site accidents, damaged materials, logistics issues, heavy machinery... The list of possible problems that can occur with stick-built construction goes on and on. The focus of modular construction is to eliminate as many of these variables as possible. Modular construction takes place in a controlled factory environment. To best explain it, it is easiest to think of a traditional assembly line that you see for most mass-produced products like cars, toys, electronics, etc... Panel Built's modular buildings are built in stages in this environment. For Panel Built, we deliver our buildings in one of two methods, knock-down or pre-assembled (depending on what is most efficient for that particular project). These two building methods allow Panel Built, Inc. to deliver modular construction projects of all shapes and sizes, capable of assembling buildings at the project site that end up being multiple times larger than what could fit on the bed of a single flatbed truck. These structures include interior buildings, metal work platforms, guard shacks, equipment buildings, military towers, cleanrooms, ballistic rated buildings, and more!

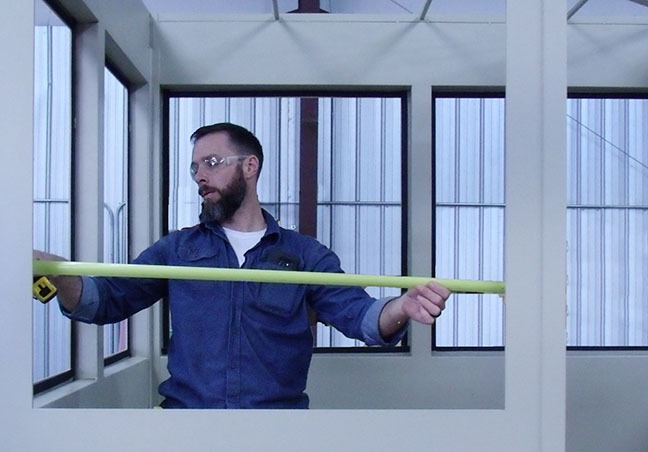

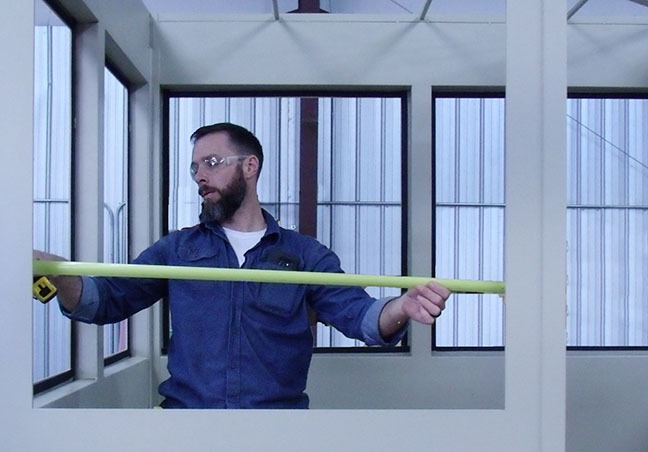

As we stated before, traditional stick-built construction open projects up to many variables due to the uncontrollable nature of a construction site. These uncertainties can lead to project delays, damaged materials, loss time accidents, and a subpar final product. By fabricating our structures in a controlled, factory environment the majority of these can be eliminated. Our buildings are fabricated in stages. From one step to the next, the building is in the hands of a highly trained professional who specializes in their trade. Increasing their experience, familiarity with the product, and providing a consistent, controlled environment minimizes the error that can occur in the construction process. Many of our buildings are entirely fabricated in our facilities, meaning they are simply delivered to the project ready to be anchored into place and hooked into a power source. However, in order to get to this point, the building must get the "All Clear" for shipping from our factory. Each and every one of our pre-assembled modular buildings is given a 36 point inspection by a member of our engineering department. This standardized procedure was developed to ensure consistency and provide 100% satisfaction. This includes ensuring all buildings are perfectly weatherproofed, have totally clean walls/floors, properly installed tiling, secured doors, and much more. Once all of these aspects have been double-checked, only then will the building be packaged for shipping.

As we stated before, traditional stick-built construction open projects up to many variables due to the uncontrollable nature of a construction site. These uncertainties can lead to project delays, damaged materials, loss time accidents, and a subpar final product. By fabricating our structures in a controlled, factory environment the majority of these can be eliminated. Our buildings are fabricated in stages. From one step to the next, the building is in the hands of a highly trained professional who specializes in their trade. Increasing their experience, familiarity with the product, and providing a consistent, controlled environment minimizes the error that can occur in the construction process. Many of our buildings are entirely fabricated in our facilities, meaning they are simply delivered to the project ready to be anchored into place and hooked into a power source. However, in order to get to this point, the building must get the "All Clear" for shipping from our factory. Each and every one of our pre-assembled modular buildings is given a 36 point inspection by a member of our engineering department. This standardized procedure was developed to ensure consistency and provide 100% satisfaction. This includes ensuring all buildings are perfectly weatherproofed, have totally clean walls/floors, properly installed tiling, secured doors, and much more. Once all of these aspects have been double-checked, only then will the building be packaged for shipping.

Overall, utilizing modular construction methods are an excellent way to best ensure a quality building project, and it is the building method that Panel Built, Inc. has relied on for over 25 years of business. Although all Panel Built buildings are fabricated off-site, each and every building is designed 100% to customer specifications. Additionally, the materials utilized in each project can be altered to provide the building with specific qualities, such as fire resistance, sound-dampening, high insulation, and even ballistic (bullet/blast resistant) capabilities. If you have any questions about our modular buildings or would like to get a quote on a modular building of your own, give us a call at 800.636.8373, send us an email to info@Panelbuilt.com, or let us know in our LiveChat in the bottom-right of the page.

What is Modular Construction?

Modular construction is a building method that has been in use since the 19th century. Since its origination, modular construction has been developed specifically to deliver consistent, quality building projects. With traditional construction methods, all of the building construction occurs at the project site. Because each job site, construction crew, and project is different, this can create a lot of variables. High foot traffic, inconsistent labor quality, inclement weather, on-site accidents, damaged materials, logistics issues, heavy machinery... The list of possible problems that can occur with stick-built construction goes on and on. The focus of modular construction is to eliminate as many of these variables as possible. Modular construction takes place in a controlled factory environment. To best explain it, it is easiest to think of a traditional assembly line that you see for most mass-produced products like cars, toys, electronics, etc... Panel Built's modular buildings are built in stages in this environment. For Panel Built, we deliver our buildings in one of two methods, knock-down or pre-assembled (depending on what is most efficient for that particular project). These two building methods allow Panel Built, Inc. to deliver modular construction projects of all shapes and sizes, capable of assembling buildings at the project site that end up being multiple times larger than what could fit on the bed of a single flatbed truck. These structures include interior buildings, metal work platforms, guard shacks, equipment buildings, military towers, cleanrooms, ballistic rated buildings, and more!

Modular construction is a building method that has been in use since the 19th century. Since its origination, modular construction has been developed specifically to deliver consistent, quality building projects. With traditional construction methods, all of the building construction occurs at the project site. Because each job site, construction crew, and project is different, this can create a lot of variables. High foot traffic, inconsistent labor quality, inclement weather, on-site accidents, damaged materials, logistics issues, heavy machinery... The list of possible problems that can occur with stick-built construction goes on and on. The focus of modular construction is to eliminate as many of these variables as possible. Modular construction takes place in a controlled factory environment. To best explain it, it is easiest to think of a traditional assembly line that you see for most mass-produced products like cars, toys, electronics, etc... Panel Built's modular buildings are built in stages in this environment. For Panel Built, we deliver our buildings in one of two methods, knock-down or pre-assembled (depending on what is most efficient for that particular project). These two building methods allow Panel Built, Inc. to deliver modular construction projects of all shapes and sizes, capable of assembling buildings at the project site that end up being multiple times larger than what could fit on the bed of a single flatbed truck. These structures include interior buildings, metal work platforms, guard shacks, equipment buildings, military towers, cleanrooms, ballistic rated buildings, and more!How Does Modular Construction Emphasize Quality?

As we stated before, traditional stick-built construction open projects up to many variables due to the uncontrollable nature of a construction site. These uncertainties can lead to project delays, damaged materials, loss time accidents, and a subpar final product. By fabricating our structures in a controlled, factory environment the majority of these can be eliminated. Our buildings are fabricated in stages. From one step to the next, the building is in the hands of a highly trained professional who specializes in their trade. Increasing their experience, familiarity with the product, and providing a consistent, controlled environment minimizes the error that can occur in the construction process. Many of our buildings are entirely fabricated in our facilities, meaning they are simply delivered to the project ready to be anchored into place and hooked into a power source. However, in order to get to this point, the building must get the "All Clear" for shipping from our factory. Each and every one of our pre-assembled modular buildings is given a 36 point inspection by a member of our engineering department. This standardized procedure was developed to ensure consistency and provide 100% satisfaction. This includes ensuring all buildings are perfectly weatherproofed, have totally clean walls/floors, properly installed tiling, secured doors, and much more. Once all of these aspects have been double-checked, only then will the building be packaged for shipping.

As we stated before, traditional stick-built construction open projects up to many variables due to the uncontrollable nature of a construction site. These uncertainties can lead to project delays, damaged materials, loss time accidents, and a subpar final product. By fabricating our structures in a controlled, factory environment the majority of these can be eliminated. Our buildings are fabricated in stages. From one step to the next, the building is in the hands of a highly trained professional who specializes in their trade. Increasing their experience, familiarity with the product, and providing a consistent, controlled environment minimizes the error that can occur in the construction process. Many of our buildings are entirely fabricated in our facilities, meaning they are simply delivered to the project ready to be anchored into place and hooked into a power source. However, in order to get to this point, the building must get the "All Clear" for shipping from our factory. Each and every one of our pre-assembled modular buildings is given a 36 point inspection by a member of our engineering department. This standardized procedure was developed to ensure consistency and provide 100% satisfaction. This includes ensuring all buildings are perfectly weatherproofed, have totally clean walls/floors, properly installed tiling, secured doors, and much more. Once all of these aspects have been double-checked, only then will the building be packaged for shipping.

What Happens On-Site?

Finally, when our pre-assembled buildings are delivered to the project site, there are only a few steps remaining before the building is completely operational. With all our buildings, they will be delivered to the project site atop a flatbed truck. From there the building can be off-loaded via forklift or crane, depending on the size of the building. The crane/forklift will then carry the building to it's final destination where it should be placed atop a concrete slab. The buildings have convenient tabs connected to the base that allows for quick and secure anchoring to the pad. Finally, the building only needs to be connected to a power source, and it is fully operational. By minimizing the amount of work left to do at the job site, modular construction minimizes the environmental hazards that traditional construction incurs. Not only do you see an increase in the overall quality of the building, there is also a reduction in the amount of disruption at the project site, making modular construction a fantastic option for facilities that cannot shut down/workaround long construction schedules. With no fabrication on-site, the pre-assembled buildings minimize the amount of waste at the job site (unpackaging the building) and for the entire building project. For our Knock-Down buildings, the process is actually pretty similar. The majority of the building & structure is fabricated off-site in our modular construction facility. However, "knock-down" buildings are generally much larger than our pre-assembled buildings and are therefore more easily transported to the project site in a sort of 'kit' that includes all of the materials needed to have the building fully installed. These 'knock down' buildings will typically be modular offices, though they can also include exterior buildings like equipment buildings, pump houses, guard booths, substation buildings, and more!Overall, utilizing modular construction methods are an excellent way to best ensure a quality building project, and it is the building method that Panel Built, Inc. has relied on for over 25 years of business. Although all Panel Built buildings are fabricated off-site, each and every building is designed 100% to customer specifications. Additionally, the materials utilized in each project can be altered to provide the building with specific qualities, such as fire resistance, sound-dampening, high insulation, and even ballistic (bullet/blast resistant) capabilities. If you have any questions about our modular buildings or would like to get a quote on a modular building of your own, give us a call at 800.636.8373, send us an email to info@Panelbuilt.com, or let us know in our LiveChat in the bottom-right of the page.