How Do You Build An Office In A Warehouse?

Building an office within a warehouse has never been easier when using Panel Built's 'knock-down' panelized, office systems. With a prefabricated office design, all of the offices designing and engineering have already been taken care of, minimizing the amount of work required on-site. With your warehouse office, Panel Built includes all of the materials needed to complete your new modular office project and includes a step by step installation guide to ensure proper and simple installation. Additionally, since every Panel Built warehouse office system is built 100% to customer specification, you will receive our Customer Package which holds a full set of drawings, including building elevations, channel layouts, panel layouts, electrical, roof, and ceiling layouts.

We have assembled the simple steps it takes using Panel Built's Warehouse Office Systems to help answer,

How Do You Build An Office In A Warehouse?

- Prep The Site - Ensure Space is Clear/Clean

- Building Layout - Measure the Space & Compare to Plans

- Start Your Wall At Corner - Fasten Base Channel Along Outline & Insert Wall Panels

- Insert Corner Post - Install Corner Post At Wall Corner

- Continue Walls - Using Binder Post System, Continue Wall Along Base Channel

- Cap Walls With Top Channel - Fasten to Top of Wall Panel

- Install B-Deck Roof Atop Top Channel - Place Deck & Fasten to Top Channel

Get a Quote To Build Your Own Warehouse Office!

To help provide some additional context for these steps, we will go through our installation procedure one by one. Of course, as you should do with all modular construction installations, we should begin with the preparation of the job site.

Site Preparation

NOTE: One of the primary benefits of modular construction is the ability to have the site prep and fabrication stages of the project occurring simultaneously. In traditional construction, the structure can only start being built once the site is ready. However, with modular, the building is already being fabricated at our modular construction facility while the job site is repaired. With these two processes occurring at the same time, we see overall shorter project times.

One key indicator of a successful warehouse office build is the preparation of the area before the actual install begins. This is the first step to ensuring a quick and error-free project. In most modular office projects, site prep mostly consists of cleaning and clearing the site of any obstructions.

When the materials are delivered to the site, good organization of materials will help reduce the possibility of mistakes and allow for the entire installation to move more swiftly. Additionally, having a clean and clear job site helps reduce the chance of accidents due to hazards. This not only helps preserve your new office but also increases the safety of your installers on-site

Drawing The Building's Layout

Next, you will want to determine where the building will be in your warehouse facility by using a chalk line to layout the interior dimensions of the modular office. Make sure to have 90-degree angles for all of the building corners. You will want to double-check the layout and dimensions you have drawn out, match the dimensions provided on the customer package. For rectangular rooms, this can be done by measuring the distance from one corner of the room to its opposite corner. Then do the same for the remaining two corners. If the measurements are equal, your layout should be 'square.'

Laying & Fastening Base Channel

Next, line your base channel along the modular office's outline you drew out in the previous step. Use the provided fasteners, 1/4" nylon anchors, to fasten the channel securely to the concrete floor with the fasteners spaced every 18" in the center of the channel. Use a 10" Phillips pan head screw when installing base channel into a wooden floor.

Starting Your Wall

After fastening your base channel, you will insert the wall panels into the channel. You will want to start at one of the office's corners (if possible) in order to provide stability to the wall system. Install the first panel with its edge even with the interior corner point. To help, putty knives can be used to guide the wall panel into place. Ensure the wall is plumb in both directions before securing the panel to the base channel with #10 x 1 Yi” Pan Head Self Drilling Tek Screws.

For two or three wall installations (using an existing wall to enclose the envelope), attach a wall start to the pre-existing wall utilizing the appropriate fasteners (will change based on wall material: either nylon anchors or #10 Pan Head screws).

Like previously, ensure the wall start is straight up and down before fastening to the existing wall and place the wall panel into the base channel/wall start corner, starting the wall. Again, ensure the wall is plumb before fastening to the channels.

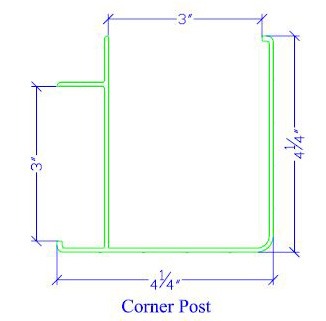

Insert Corner Post to Attach Panels

After securing your first wall panel, you can proceed by installing a corner post over the edge of the panel. It is important to note: you must install your first wall panel into the short end of the post! The long edge will be used as an end piece in order to account for any wall growth over the course of the wall installation.

Panel Built corner posts are designed to allow up to 3" of wall panel growth if needed. You can also use a putty knife to guide the corner post onto the panel. When correctly attached, fasten the top and bottom of the post using #10 Pan Head Self Drilling Tek Screws.

Continuing The Wall Panel System

Now that you have secured your first wall panel, it is time to begin extending the wall using our binder post system. Panel Built's binder post assembly each consists of four separate components: Two Hat Channels and Two Snap-In Covers. To begin making the binder post, fast two hat channels together using #12x3/4# hex head self-drilling screws. You can begin assembling all of the binder posts, EXCEPT FOR TWO. It is important that you leave these unassembled as they will fit into the final panel to complete the office. To continue your wall place the assembled binder post over the end of your first corner wall panel.

With this post in place, slide the next panel over the edge of the binder post while allowing for 1/8" space between the panels' edges and the binder posts. Continue to assemble until the end of the base channel is reached where another corner post will be installed.