Roof and Ceiling

Specifications

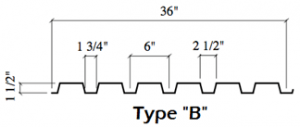

B Decking

Type B (wide rib) deck provides excellent structural load carrying capacity per pound of steel utilized, and its nestable design eliminates the need for die set ends. 1" or more rigid insulation is required for Type B deck. Acoustical deck (Type BA, BIA) is particularly suitable in structures such as loud manufacturing areas, schools, and theatres where sound control is desirable.Acoustic perforations are located in the vertical webs where the load carrying properties are negligibly affected (less than 5%). Inert, non-organic glass fiber sound absorbing batts are placed in the rib openings to absorb up to 60% of the sound striking the deck. Batts are field installed and may require separation

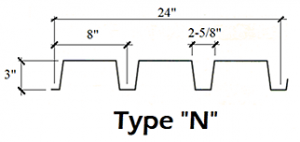

N Decking

Acoustical deck is particularly suitable in structures such as loud manufacturing areas, schools and theaters where sound control is desirable. Acoustic perforations are located in the vertical webs where the load carrying properties are negligibly affected (less than 5%). Inert, non-organic glass fiber sound absorbing batts are placed in the rib openings to absorb up to 70% of the sound striking the deck. Batts are field installed and may require separation

1/12 PITCH PANELIZED SHED ROOF W/ 9” OVERHANG

The roof shall be 3" thick composite sandwich panels. Both sides shall be stucco- embossed aluminum pre-painted white. The core shall be of 1 lb. density polystyrene foam. The entire panel shall be laminated together using a solvent free two-part polyurethane adhesive and pressure. The panels shall have formed edge connectors that are capable of being friction locked without mechanical fasteners using a full-length joint without through metal connectors. The joint shall allow lateral expansion and contraction.

1/12 PITCH PANELIZED SHED ROOF W/ 9” OVERHANG

The roof shall be 3" thick composite sandwich panels. Both sides shall be stucco- embossed aluminum pre-painted white. The core shall be of 1 lb. density polystyrene foam. The entire panel shall be laminated together using a solvent free two-part polyurethane adhesive and pressure. The panels shall have formed edge connectors that are capable of being friction locked without mechanical fasteners using a full-length joint without through metal connectors. The joint shall allow lateral expansion and contraction.

4/12 PITCH PANELIZED Gable ROOF W/ 9” OVERHANG

The roof shall be 3" thick composite sandwich panels. Both sides shall be stucco- embossed aluminum pre-painted white. The core shall be of 1 lb. density polystyrene foam. The entire panel shall be laminated together using a solvent free two-part polyurethane adhesive and pressure. The panels shall have formed edge connectors that are capable of being friction locked without mechanical fasteners using a full-length joint without through metal connectors. The joint shall allow lateral expansion and contraction.