Reducing Factory Noise and Creating an Overall Safer Workplace

Blog

It can be difficult enough to concentrate at work just in an office environment. However, for the men and women that make their living working on a factory floor, there are additional factors at play, impacting their performance and even their health.

Noise levels are a big factor impacting the efficiency and health of workers in more noisy work environments. Prolonged exposure to "noisy" environments has been linked to increased stress, an increase in accidents in the workplace, and aggressive behavior.

The United States started to take notice of these adverse effects in the early

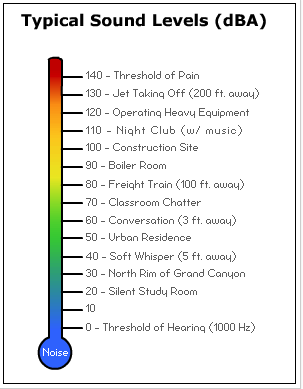

In the workplace, OSHA has since put in place their own regulations to help workers in more severe environments. For an example of some of these environments, the Occupational Safety and Health Administration (OSHA) has the chart below to help provide an understanding of the decibel levels in general life situations.

Looking at their handy chart, we can reasonably expect an office environment to land somewhere in the range of 50-70 dBA. However, in a factory or manufacturing environment that range can be anywhere from 90 to 100 dBA, even up to 120dBA at times! This level of noises creates a much more hectic environment; one that OSHA heavily regulates...

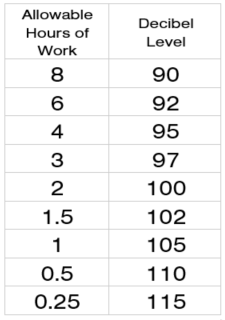

As you can see, the higher the overall decibel level becomes, the less amount of time that employees can spend continuously working in that environment. So, companies that must use loud equipment or find themselves in a naturally "noisy" environment have to find a way to protect their employees. And there are a few ways that they can do this...

Stopping Noise its Origin

One of the most effective and often used tactics in factories and public environments is the stop the noise at its source. By stopping the noise at the origin point, you are able to reduce the overall area the noise effects. For Panel Built, the way that we typically are asked to help tackle this issue is to design equipment enclosures or machinery enclosures. In fact, Panel Built works with a number of equipment and machinery manufacturer and installers to help them develop an enclosure system specifically for their product.

Using our panelized enclosure design, we are able to engineer and design an enclosure system that allows the equipment to operate under ideal conditions while reducing the overall noise level of the facility. Because Panel Built's panels are composite, we are able to configure the material inside to custom fit the application.

In the case of a sound dampening equipment enclosure, we can include sound reduction board to create a panel with a higher STC rating (Sound Transmission Class). STC ratings specifically refer to the ability of a building or wall partition to reduce the volume of sound passing through it. For Panel Built's 3" wall system, we can increase our STC rating into the 42-45 range which provides some of the greatest noise reduction in our industry.

Self Hearing Protection

Another way that companies (and OSHA) help to protect workers'

These hearing protections are needed for all workers who are exposed to 8-hour at or above an average noise level of 85 dB. In these cases, employees should be able to choose between at least one variety of hearing plug and one variety of hearing muff. With the help from a person trained in hearing protection, an employee should decide which option works best for them based on their working environment and overall comfort level.

Factory Layout

If a factory or manufacturing facility is still in its design phase or being re-configured, special attention to the positioning of noise sources can go a long way towards reducing noise pollution in the facility. Put as much distance as possible between loud machinery and office spaces or other adjacent buildings.

By providing the additional space between the two areas, you allow the office space in the manufacturing facility to be impacted by the noisy machinery as little as possible and it helps your facility keep up with noise pollution codes by not affecting the neighboring buildings around you.

In a facility with many sources of loud noise, do your best to group these sources together in one point in your facility. This one part of the facility will be very loud, but containing one concentrated source of noise will be much easier than many across the facility.

Also, when adding office space to a noisy facility, use materials with additional sound dampening properties. Similar to our equipment enclosures, our modular office systems can be designed to meet higher STC ratings, providing a very controlled and comfortable environment inside. Whether this space is going to be used for a supervisor's office or a break room, the area will provide a much quieter environment where the occupants can escape the chaos of the factory floor.

By taking these steps to help reduce the noise in your factory, employees will have a much easier time focusing, relaxing, and performing their duties. If you have any questions about how Panel Built can help you increase the sound control in your facility with equipment enclosures, modular office, break rooms, or machine enclosure, just give us a call at 800-636-3873, shoot us an email to info@panelbuilt.com, or just say hey to us in our LiveChat in the bottom right! We are happy to help with any of your questions or needs.