The Difference Between IBC and OSHA Stair Codes

Blog

When building a stair or ladder system in your facility, there will more than likely be a few standards for the structure to meet in order for it to satisfy your building codes. These standards for building stairs and ladder systems are set up by OSHA and IBC. OSHA, known as the Occupational Safety and Health Administration, is a United States federal agency that regulates and enforces workplace safety and health. While, on the other hand, IBC or the International Building Code is a model building code developed by the International Code Council to standardize building codes across the United States with the first edition coming out in 1997. Overall, OSHA standards generally only apply in a workplace environment with IBC codes used in most other cases.

OSHA Stairs

For stair systems to be compliant with OSHA code, the structure must first only be for the use of workers with no access to the public. Overall, They can include areas like factory floors and manufacturing spaces where only designated employees work. Therefore, they are not bound by the IBC. Instead, the Occupational Safety and Health Administration’s Fixed Industrial Stair regulations (1910.24) govern the design, construction and use of both interior and exterior stairs used to access equipment, machinery, tanks, elevated platforms, other floors or pits. Looking at the standards for an OSHA approved stair system, we are going to factor in five main areas of note: the slope of the stairs, the risers & tread, stair width, safety railing, and the stair system’s landing.

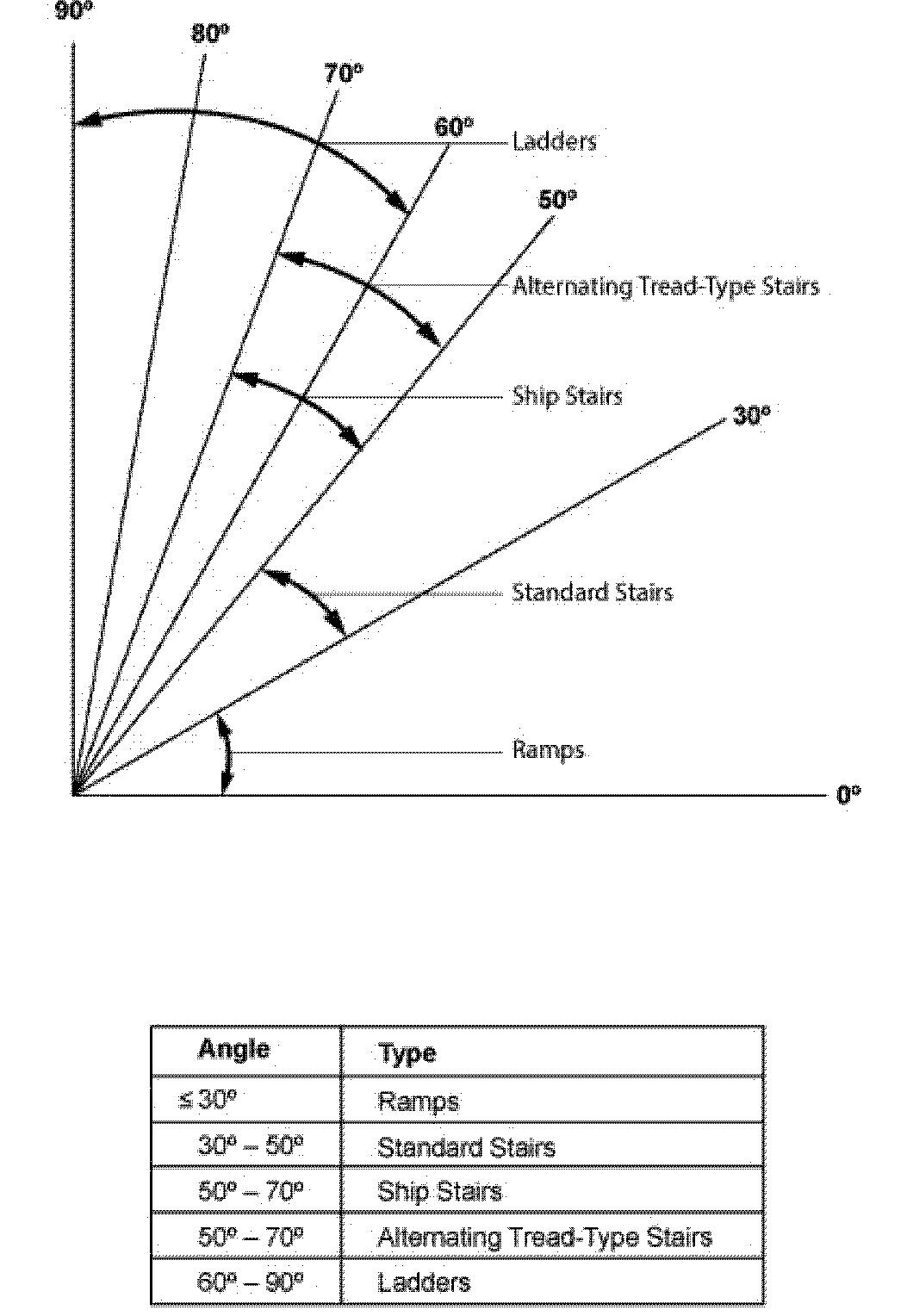

For the slope of the stair system, we are going to look at the total vertical height of the stairway from floor to landing, and then the amount of horizontal run that the stairs use to get there. Looking at the chart on the right, from osha.gov you will see the varying degrees of incline that OSHA classifies. For OSHA approved stairs, the slope of the staircase must lie in the B zone, between 30o-50o. The stair system must have a landing at the top and bottom of the stairs. If the top landing is leading to a door, there must be 22” between the end of the fully open door and the edge of the landing. The width of the stairs must be a minimum of 22” wide. OSHA requires railings on open sides of stairwells and a handrail on at least one side, preferably the right side descending at 34” high.

Get A Stair System Quote Today!

IBC Stairs

IBC Stairs

For IBC stairs, there will have considerably tougher standards because these stair systems will typically be found in areas that are open to the public and have much higher traffic than OSHA stairs. These regulations must account for the safety of every type of person — including children and the elderly. Therefore, the International Building Code must have guidelines that account for smaller people who could slip underneath handrail or between pickets. Plus, there is a larger area for traffic to move in both directions, as well as a larger landing zone for elderly people or people with poor vision.

Also, IBC codes for approved stairs are more set-in-stone than the OSHA rules. For the slope of an IBC stair system, the horizontal run of the stair systems should be 1.5 times the vertical rise. Plus, they are required to have an intermediary landing if the staircase has a rise of 12’ or more. Generally, the width of IBC stairs will be 36”, which in comparison to OSHA stairs (22”), provides a lot more room for traffic and error. And IBC stairs will have a 7”, closed riser and an 11” tread. Finally, these stair systems require rails of 42” high and handrails of 34” high on both sides of the stairwell.

For a condensed version of the differences between IBC and OSHA stair systems, check out our info sheet.

Overall, both the IBC and OSHA codes have one simple goal in common, to keep more people safe and secure throughout their day to day lives. These groups do an amazing job of not only setting up effective safety guidelines and regulations but also reassessing their work and improving them for the future. With the information they provide on proper safety protocol and statistics on workplace accidents, they allow many blue collar workers to live and work in a much healthier and secure environment. In general terms, OSHA standards are less stringent than IBC standards and are more commonly utilized in government facilities. IBC standards are preferred and more prevalent in private industry. However, both of these sets of standards have their own benefits. With IBC ensuring top-notch safety for the public, and OSHA allowing some design flexibility for facilities with complex work operations.

If you would like to see how these OSHA and IBC codes would affect your modular construction project, please contact Panel Built, Inc. at info@panelbuilt.com or call us at 800-636-3873. We’re more than happy to answer any and every question that you may have. With over 20 years in the modular construction industry, we have done projects across the United States and internationally. We are the modular construction experts.